Why Heat Pump Compressor Problems Can’t Wait

Heat pump compressor repair is one of the most critical HVAC services you may need as a homeowner. The compressor is literally the heart of your heat pump system – without it working properly, you’ll have no heating or cooling at all.

Quick Answer for Heat Pump Compressor Repair:

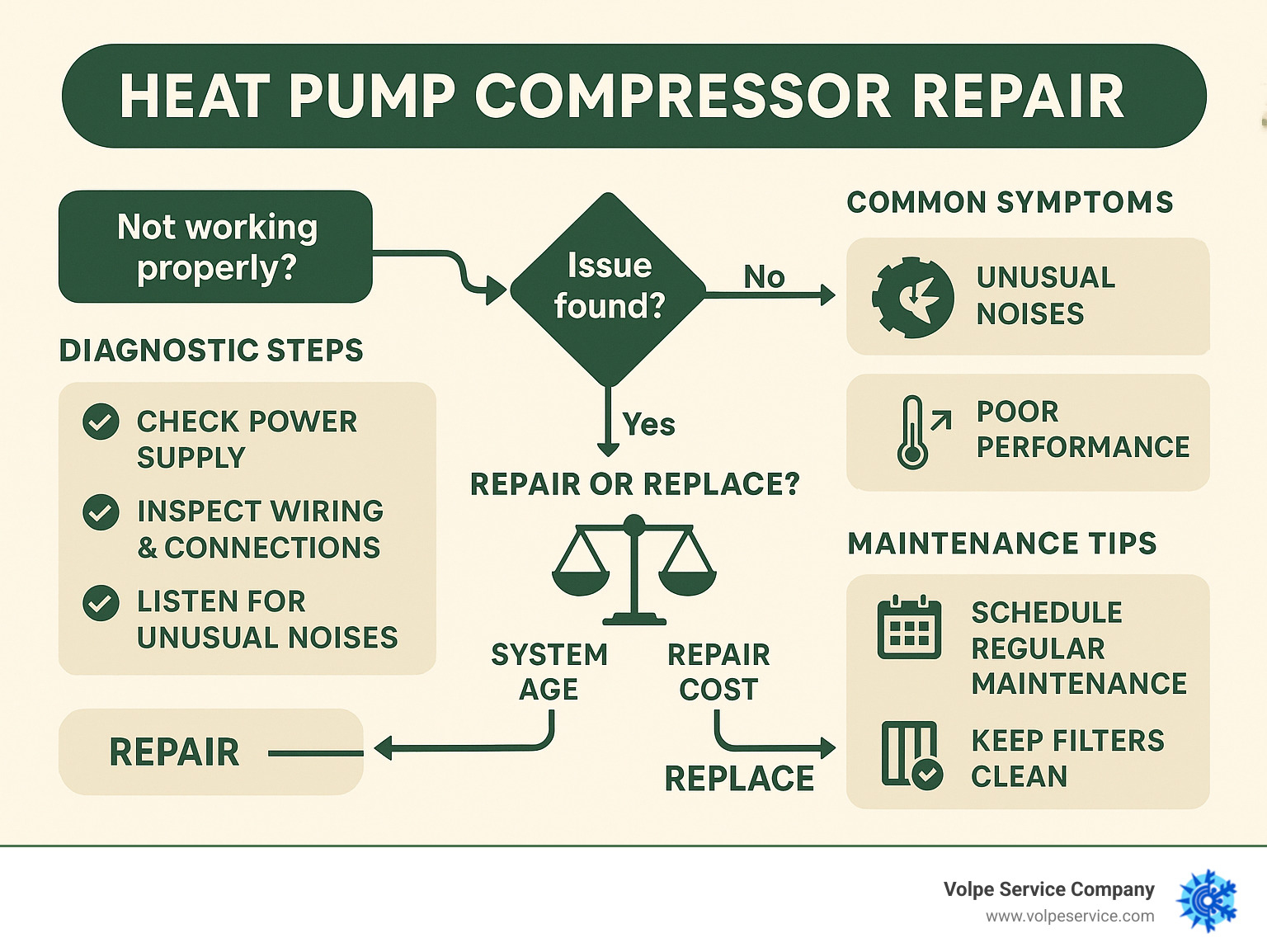

- Common signs: Unusual noises (grinding, rattling), unit won’t start, poor heating/cooling, frozen outdoor unit

- Typical causes: Electrical issues, refrigerant leaks, dirty filters, worn components

- Repair vs. replace: Systems over 10-15 years old often need full replacement

- Cost factors: Labor, parts, refrigerant type, and compressor complexity all affect price

- Professional required: This involves high-voltage electricity and regulated refrigerants

Your heat pump compressor works by pressurizing refrigerant gas and moving it between your indoor and outdoor units. This process enables the heat transfer that keeps your home comfortable year-round. When the compressor fails, it makes heat exchange impossible.

The compressor has a dual purpose – it provides both heating in winter and cooling in summer, unlike air conditioners which only cool. This makes compressor problems especially frustrating since they affect your comfort regardless of the season.

Most heat pump compressors last about 10-15 years with proper maintenance. However, issues like electrical problems, refrigerant leaks, or contamination can cause premature failure. The key is recognizing the warning signs early, before a minor repair becomes a major replacement.

What is a Heat Pump Compressor and Why is it Important?

Your heat pump compressor is truly the heart of your entire comfort system. Just like your heart pumps blood through your body, the compressor circulates refrigerant through your heat pump, making it possible to heat and cool your home year-round.

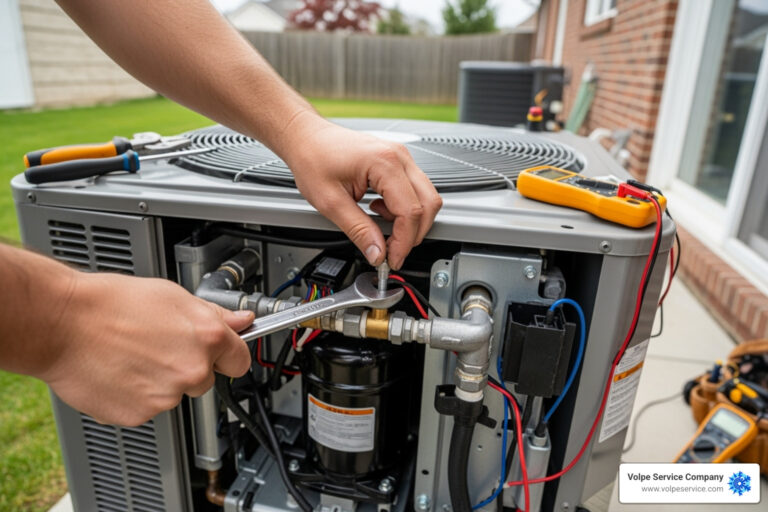

Located in that big metal box outside your house (the outdoor unit), this hardworking component has one main job: move the refrigerant between the indoor and outdoor units while controlling pressure and temperature. Without a functioning compressor, your heat pump is basically an expensive paperweight.

Here’s where it gets interesting – your compressor is a true multitasker. During summer, it pressurizes the refrigerant gas to release heat outside, keeping your home cool. Come winter, it reverses the process, pulling heat from the outdoor air (yes, even freezing air contains heat!) and pumping it inside. This continuous heat transfer process is what makes heat pumps so much more efficient than traditional heating systems.

When your compressor starts having problems, you’ll know it. Whether it’s strange noises, poor heating and cooling, or complete system failure, heat pump compressor repair becomes an urgent priority. After all, this component handles both your heating AND cooling needs.

Common Types of Heat Pump Compressors

Not all compressors are created equal. Understanding the types helps with repair and replacement decisions.

- Scroll compressors: The modern standard. They use two spiral pieces to compress refrigerant, making them quiet, reliable, and efficient.

- Rotary compressors: Often found in smaller systems, these use a spinning roller inside a cylinder. They are compact and budget-friendly.

- Reciprocating compressors: An older, durable design that works like a car’s piston. These reciprocating compressors are typically noisier and less efficient.

Compressors also vary by operation:

- Single-stage: Run at full power only, cycling on and off.

- Two-stage: Run at a lower speed most of the time, switching to full power when needed for better efficiency.

- Variable-speed: The most advanced type, adjusting speed precisely to match your home’s needs for maximum comfort and energy savings.

The Role of Refrigerant

Refrigerant is the fluid that carries heat through your system, changing between liquid and gas. The compressor’s job is to manage this refrigerant’s pressure and temperature for efficient heat transfer.

A leak in this closed-loop system forces the compressor to work harder, leading to overheating and failure, requiring heat pump compressor repair. Watch for Heat Pump Refrigerant Leaks Signs like poor performance, ice on the lines, or hissing sounds.

Environmental considerations are also key. Older R-22 (Freon) refrigerant is being phased out for damaging the ozone layer. Modern systems use eco-friendly refrigerants like R-410A. If your older R-22 system has a major leak, replacement is often more cost-effective than a repair due to the high cost and scarcity of R-22.

Diagnosing Compressor Problems: Signs and Symptoms

Your heat pump has a way of telling you when something’s wrong – you just need to know how to listen. The sooner you catch the warning signs of compressor trouble, the better chance you have of avoiding a costly emergency repair. Your system communicates its health through sounds, performance changes, and energy use.

Common Causes That Require Heat Pump Compressor Repair

Compressor failure is usually caused by an underlying issue that develops over time, requiring professional heat pump compressor repair.

- Electrical problems: Issues like a bad start capacitor, loose wiring, or a tripped circuit breaker can prevent the compressor from starting or running properly.

- Refrigerant leaks: Low refrigerant forces the compressor to work overtime, causing it to overheat and wear out prematurely.

- Contamination: Dirt, debris, or moisture in the refrigerant lines can damage the compressor’s internal parts. This often results from improper installation or a system breach.

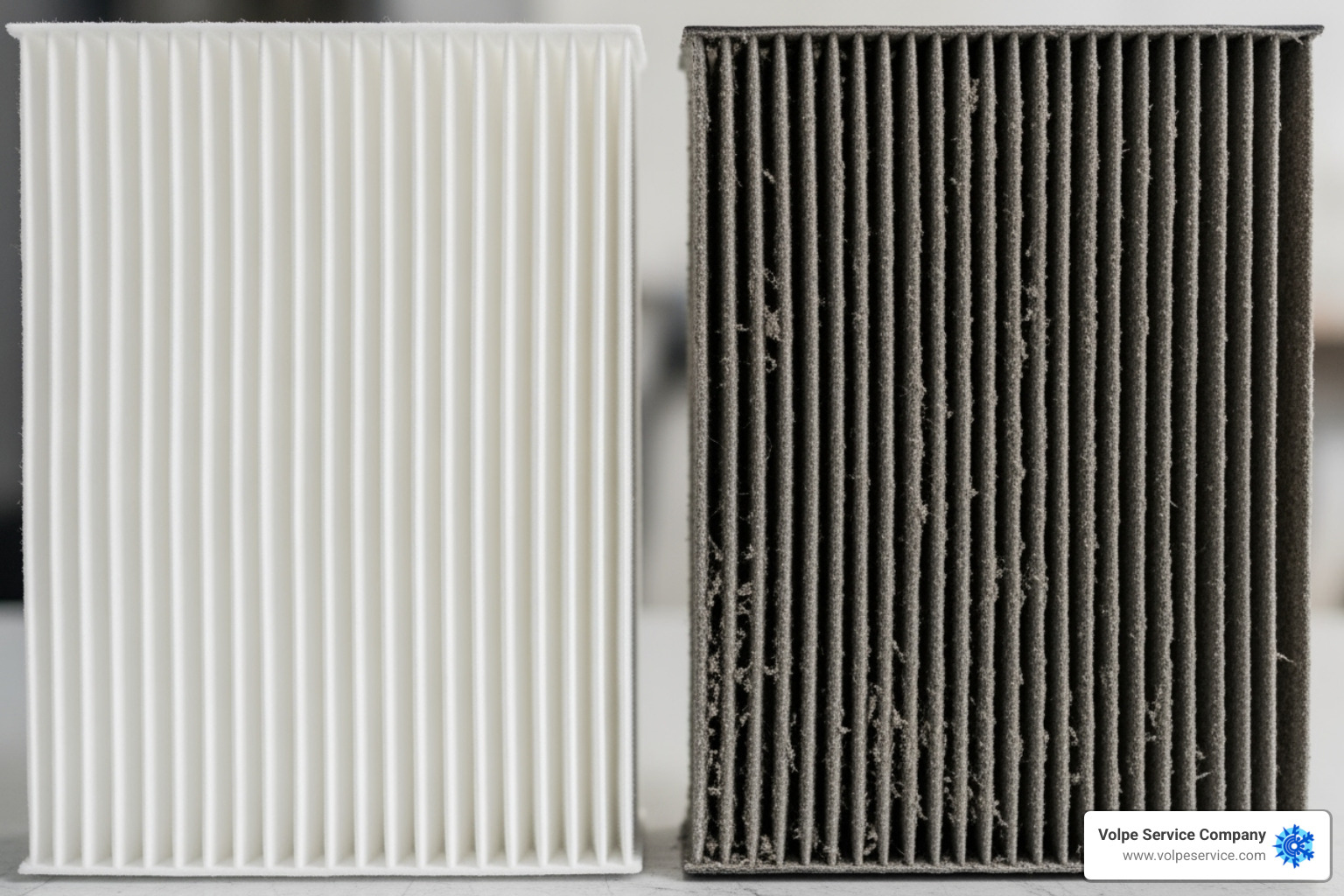

- Lack of maintenance: Clogged filters and dirty coils are major culprits. They restrict airflow and force the compressor to work much harder, leading to strain and failure.

- Overheating: This is the end result of many other problems, including low refrigerant or dirty coils. Excessive heat damages critical motor components, often beyond repair.

Our guide on Professional Heat Pump Repair Signs can help you determine when to call for help.

Telltale Noises and What They Mean

A normal heat pump hums gently, but unusual noises are a cry for help. Learning to identify them can prevent expensive repairs.

- Grinding or rattling: A serious red flag indicating loose or rubbing metal parts inside the compressor. Turn the system off immediately.

- Hissing or gurgling: Usually points to a refrigerant leak, especially if accompanied by poor performance.

- Screeching or squealing: This high-pitched sound often means internal bearings are failing.

- Loud humming without starting: Suggests an electrical issue, like a failing start capacitor, is preventing the compressor from turning on.

For a complete breakdown, see our article on Heat Pump Strange Noises.

Performance Issues to Watch For

Performance issues are just as critical as strange noises. Watch for these red flags:

- Poor heating or cooling: The system runs constantly but can’t reach the set temperature, suggesting the compressor isn’t building enough pressure.

- System won’t turn on: The compressor may have failed completely or has an electrical problem preventing it from starting.

- Short cycling: The unit turns on and off in rapid, short bursts. This wasteful pattern, explained in our Heat Pump Cycling Issues article, is hard on your equipment and can be caused by overheating or low refrigerant. This is a form of short cycling.

- A completely frozen outdoor unit: A unit encased in ice (beyond normal frost) points to serious issues like low refrigerant or blocked airflow, which strain the compressor.

- Rising energy bills: A sudden spike in your utility bills often means the compressor is working inefficiently to compensate for an underlying problem.

Early intervention can be the difference between a simple repair and a full system replacement.

The Heat Pump Compressor Repair vs. Replacement Decision

When your heat pump compressor fails, you face a major decision: should you invest in heat pump compressor repair, or is it time to replace the entire system? The best choice depends on several key factors.

| Factor | Compressor Repair | Full System Replacement |

|---|---|---|

| System Age | Generally recommended for systems under 10 years | Often recommended for systems 10-15+ years old |

| Warranty | May cover parts if still under compressor warranty | Entire new system comes with a new, comprehensive warranty |

| Efficiency | Maintains current efficiency (which might be low) | Significant efficiency gains with new, high-SEER models |

| Future Reliability | Other old components may soon fail, leading to more repairs | All new components mean higher reliability for years |

| Cost | Lower upfront cost, but potentially higher cumulative over time | Higher upfront cost, but better long-term value and savings |

| Refrigerant | May require costly R-22 if system is old | Uses modern, environmentally friendly refrigerants |

Think of your heat pump like a car. You’d fix the engine on a three-year-old car, but you might replace a 15-year-old car that needs constant repairs.

The Cost of Heat Pump Compressor Repair

Heat pump compressor repair is a complex job requiring certified technicians to safely handle high-voltage electricity and regulated refrigerants. The total cost is influenced by several factors:

- Labor costs: Reflect the specialized training and time required for the repair.

- Parts cost: The compressor itself is a major expense. Advanced variable-speed models cost more than basic single-stage units.

- Refrigerant cost: Replacing refrigerant adds to the cost, especially for older, phased-out R-22. Modern R-410A is more affordable.

- Warranty: A compressor still under its typical 10-year parts warranty can make repair a much more affordable option, though labor is not usually covered.

For more details, see our heat pump repair services.

When to Replace the Entire Heat Pump System

Sometimes, a full system replacement is a smarter investment than heat pump compressor repair. Consider replacement if:

- Your system is over 10-15 years old. A failed compressor is often the first of many age-related component failures. Replacing just one part on an old system can be a temporary fix.

- You’ve had frequent breakdowns. If you’re already paying for regular repairs, a new system offers better long-term reliability.

- Your system uses R-22 refrigerant. This outdated refrigerant is expensive and being phased out, making future repairs costly and difficult.

- The repair cost is high. A common guideline is the “50% rule”: if a repair costs 50% or more than a new system, replacement is usually the better value.

- You want better energy efficiency. Modern heat pumps are significantly more efficient, and the energy savings can help offset the cost of a new unit.

Our article Is It Worth Installing a Heat Pump can help you weigh the pros and cons for your New Jersey home.

Proactive Maintenance to Extend Compressor Life

The best heat pump compressor repair is the one you never need. Proactive maintenance is like a regular check-up for your system, saving you from major pain and expense later. The good news is that many tasks are straightforward, and the payoff in reliability and lower energy bills is huge.

DIY Maintenance Tasks

A few simple DIY tasks can make a huge difference in preventing breakdowns and extending your compressor’s life.

- Change air filters regularly: This is the most important task. A clogged filter restricts airflow, forcing the compressor to overwork and overheat. Plan on changing your air filters every 1-3 months.

- Keep the outdoor unit clear: Ensure at least two feet of clearance around your outdoor unit. Remove leaves, grass, and other debris that can block airflow and strain the system.

- Check thermostat settings: Before calling for service, confirm your thermostat is in the correct mode (heating/cooling) with fresh batteries. Simple setting errors can mimic compressor problems.

- Visually inspect the unit: Periodically look for obvious damage like bent fins or ice buildup. Spotting issues early can prevent major repairs.

The Importance of Professional Tune-Ups

While DIY tasks help, nothing replaces a professional tune-up. We recommend annual service visits (spring and fall) to catch issues before they require heat pump compressor repair. Our technicians perform several critical checks:

- Refrigerant level checks: We ensure your system has the precise amount of refrigerant needed for efficient operation and check refrigerant levels for leaks.

- Electrical connection testing: We tighten connections and test components to prevent electrical failures, a leading cause of compressor damage.

- Professional coil cleaning: We thoroughly clean coils and components to ensure optimal heat transfer and reduce strain on the compressor.

- Lubricating moving parts: This reduces friction and wear, extending the life of your system’s components.

This proactive approach keeps your system efficient and reliable. For comprehensive care, explore our Chester NJ Heat Pump Maintenance services.

Frequently Asked Questions about Heat Pump Compressors

We’ve heard just about every heat pump question imaginable. Here are the most common ones homeowners ask about heat pump compressor repair.

How long should a heat pump compressor last?

A well-maintained heat pump compressor typically lasts 10-15 years. Key factors affecting its lifespan include usage patterns, the quality of the unit, and most importantly, regular professional maintenance. Consistent tune-ups can help your compressor reach or even exceed this range.

Can I replace a heat pump compressor myself?

No, this is a job strictly for certified professionals. Heat pump compressor repair and replacement involve high-voltage electricity and EPA-regulated refrigerants, both of which pose serious safety risks. Attempting a DIY repair can lead to injury, further system damage, and voided warranties. It requires specialized tools and training to be done safely and correctly.

Is a noisy heat pump compressor dangerous?

While the noise itself isn’t typically a direct safety hazard, it’s a critical warning sign. Ignoring unusual noises like grinding, rattling, or screeching can be dangerous for your HVAC system’s health. These sounds often indicate failing internal parts, and letting them continue will likely lead to a complete compressor failure and a much more expensive repair or replacement. It’s crucial to have any strange noises inspected by a professional immediately.

Trust the Experts with Your Heat Pump Needs

When facing a heat pump issue, deciding between heat pump compressor repair and a full system replacement can be daunting. You don’t have to make this choice alone.

At Volpe Service Company, we use a data-driven approach to give you clear answers. Since 1963, our family-owned business has provided New Jersey homeowners with honest, professional HVAC solutions. We use advanced diagnostics to pinpoint the problem and educate you on the best course of action.

We’ll explain if a repair is cost-effective or if a replacement offers better long-term value. Our guaranteed service means we stand behind our work and recommendations. Whether you’re hearing strange noises or dealing with poor performance, our certified technicians have the expertise to find the right solution.

Ready to restore your home’s comfort? Contact us for expert heating repair in East Hanover, NJ. Let us help you make a confident decision about your HVAC investment.