Why Your Boiler’s Heart Matters: Understanding Pump Replacement

Boiler pump replacement is one of the most common heating repairs New Jersey homeowners face, especially during the cold winter months when a failing pump can leave you without heat or hot water.

Quick Answer: Signs You Need Boiler Pump Replacement

- No heat reaching radiators despite boiler running

- Strange noises like grinding, banging, or vibrating

- Cold spots in radiators (warm at top, cold at bottom)

- Leaking water around the pump area

- Boiler overheating due to poor circulation

- No hot water production

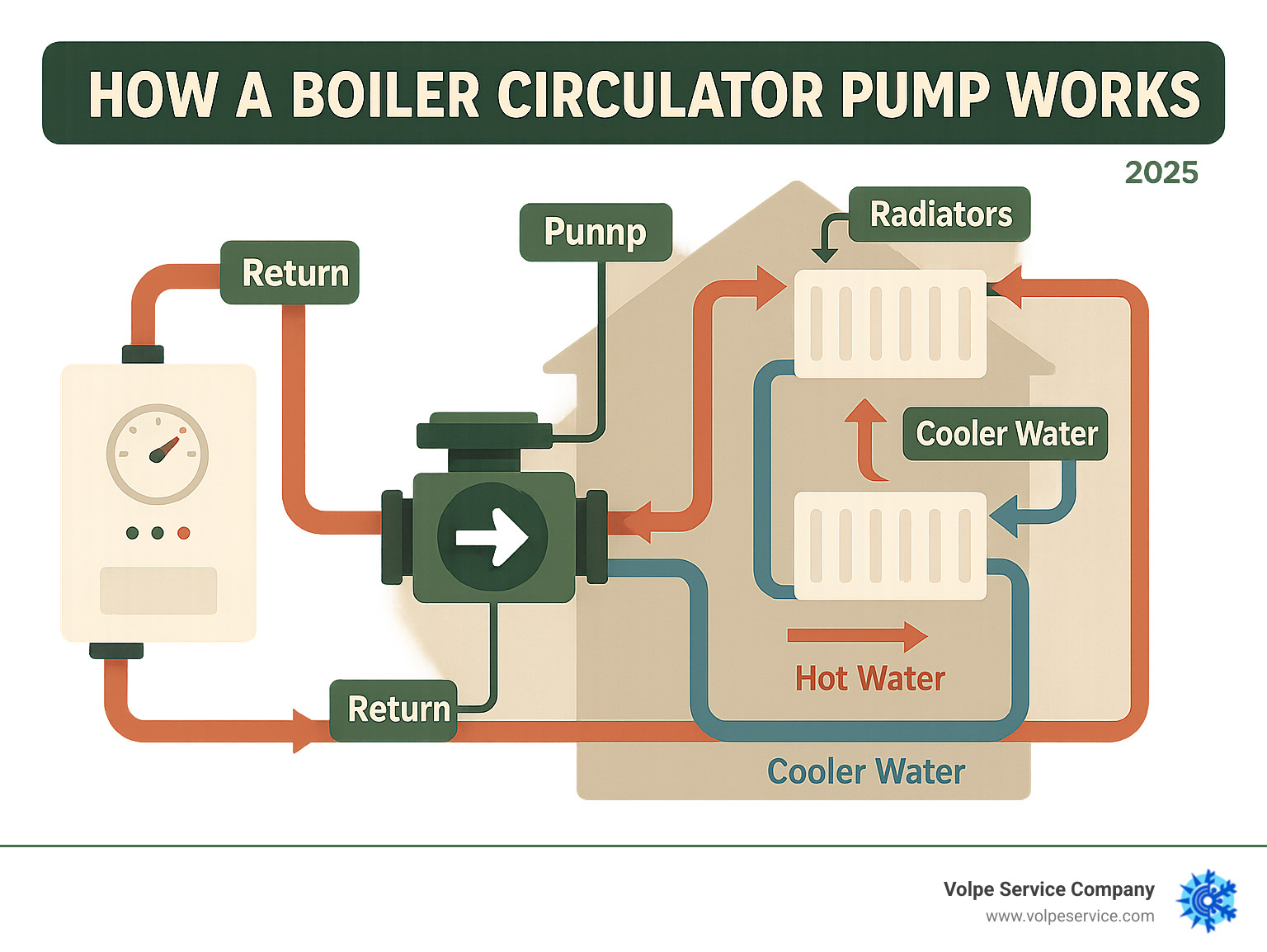

Your boiler’s circulator pump is like the heart of your heating system. It pushes hot water through pipes to radiators and back to the boiler for reheating. When this pump fails, your entire home comfort system breaks down.

The good news? Most pump problems show clear warning signs before complete failure. Understanding these signs can save you from a cold night and expensive emergency repairs.

A typical boiler pump lasts 10-20 years with proper maintenance. However, factors like system age, water quality, and regular servicing can significantly impact its lifespan. Whether you’re dealing with a minor issue or need complete replacement, knowing what to expect helps you make informed decisions about your home’s heating system.

Is Your Boiler Pump Failing? Telltale Signs and Causes

If your home feels like an icebox despite the boiler running, your boiler pump replacement might be overdue. The circulator pump is the heart of your heating system, pushing hot water to your radiators. When it fails, the hot water goes nowhere, but the pump usually gives you warning signs first.

No heat or hot water is the most obvious red flag. Your boiler runs, but radiators stay cold. You might also notice radiators are cold at the bottom but warm at the top, a classic sign of poor circulation.

Banging or grinding noises are another common symptom. Grinding often means worn-out bearings, while banging can point to air trapped in the system. A persistent hum without water flow could mean the motor is trying to turn a seized impeller.

Leaking water from the pump should never be ignored. Drips from worn seals or corrosion can lead to significant water damage.

Boiler overheating occurs when the pump can’t move water away from the boiler fast enough, causing safety systems to shut it down. For more details on these signs, see our guide on boiler repair indicators.

Common Reasons for Pump Failure

Boiler pumps don’t last forever. The most common culprits for failure include:

- Age and corrosion: After years of service, seals wear out and metal components rust.

- System sludge and debris: Rust particles and limescale build up, acting like mud that clogs the pump’s impeller and overworks the motor.

- Airlocks in the system: Trapped air prevents water circulation, causing the pump to run dry or overheat.

- Incorrect installation or electrical issues: Poor wiring, power surges, or control board problems can damage the pump’s motor.

Diagnosing the Problem

Before assuming you need a full boiler pump replacement, a quick diagnosis can clarify the issue.

- Check for power: Ensure the pump is receiving electricity. For safety, electrical work should be left to a professional.

- Listen for sounds: Grinding points to worn bearings, while gurgling or banging suggests trapped air that needs to be bled from the system.

- Inspect for leaks: Look for moisture or corrosion around the pump. A loose fitting might just need tightening, but corroded parts mean it’s time to call a pro.

- Feel for vibration: If the pump vibrates but doesn’t move water, the impeller may be seized. A gentle tap on the pump body might free it temporarily, but this is rarely a permanent fix.

If your boiler is making knocking sounds, our guide can help you understand the cause: Boiler making knocking sounds? Find out why. Understanding these signs helps you have a more informed conversation with your HVAC technician.

The Boiler Pump Replacement Process: A Step-by-Step Guide

When your boiler pump fails, understanding the boiler pump replacement process helps you know what to expect. It’s a precise job that involves both water and electricity, so safety is paramount.

The process starts with powering down the system at both the boiler switch and the circuit breaker. Safety first.

Next, a technician will isolate the pump using the valves on either side. This allows work on the pump without draining the entire heating system. If your system lacks these valves, a full system drain is necessary.

Draining the section around the pump is next. Even with isolation valves, some water will spill, so towels and a bucket are essential.

Disconnecting the wiring is done carefully, often after taking a photo to ensure correct reconnection. Removing the old pump involves unbolting it from the pipework. Corroded bolts may require some patience.

Installing the new pump is the reverse process, with two critical details: using new gaskets to create a watertight seal and ensuring the pump’s flow direction arrow aligns with the system’s water flow. Installing it backward will result in no heat.

After reconnecting everything, the system is refilled and bled of any trapped air. Air pockets prevent proper circulation, so the pump and all radiators must be bled, starting from the lowest point in the home.

For more on larger jobs, our step-by-step guide to boiler installation covers similar principles.

DIY vs. Professional Boiler Pump Replacement: Making the Right Choice

Deciding between DIY and professional boiler pump replacement is a common question. While saving money is tempting, this job carries significant risks.

- Electrical Safety: Working with electrical components near water is dangerous. A mistake can cause serious injury.

- Water Damage: An improperly tightened connection or forgotten gasket can lead to a flood, with repair costs far exceeding the price of professional installation.

- System Pressure: Heating systems are pressurized. Incorrect handling can cause damage or create unsafe conditions.

- Gas Safety: On gas boilers, any work on the system can inadvertently affect gas lines. This work should only be done by licensed professionals.

Professional expertise from a company like Volpe Service Company provides peace of mind. Since 1963, we’ve ensured safe, compliant installations for New Jersey homeowners. A professional can also diagnose underlying system issues that may have caused the pump to fail in the first place.

If you’re leaning toward professional help, don’t hesitate to contact Volpe Service Company for professional boiler pump replacement.

Key Steps for a Successful Replacement

Whether DIY or pro, these are the essential steps for a successful boiler pump replacement:

- Power Down the System (Boiler and Circuit Breaker)

- Isolate the Pump (Using Isolation Valves)

- Drain the Section

- Disconnect Wiring

- Unbolt and Remove Old Pump

- Install New Gaskets and Pump (Check Flow Arrow)

- Reconnect and Refill

- Bleed the System (Pump and Radiators)

Understanding the Costs: Repair vs. Replacement

When your boiler pump acts up, you face a key decision: repair or replace? The right choice can save you money and prevent future headaches, especially during cold New Jersey winters. The decision involves more than just the initial price tag; it’s about long-term reliability. At Volpe Service Company, our data-driven approach provides honest, straightforward advice for your situation.

Boiler pump replacement costs depend on the pump type, system complexity, and labor time. A job can be quick if the pump is accessible, or take hours if the system needs a full drain.

Here’s how repairs stack up against replacement:

| Aspect | Repairing a Minor Issue (e.g., seized impeller, loose wiring) | Full Boiler Pump Replacement |

|---|---|---|

| Initial Cost | Typically lower, focusing on specific parts or labor for diagnosis/adjustment. | Higher upfront cost, covering the new pump and more extensive labor. |

| Longevity | May offer a temporary fix; the underlying issue (age, wear) could lead to future problems. | Provides a new component with its full expected lifespan (often 10-20 years). |

| Reliability | Risk of recurring issues, especially if the pump is old or has multiple underlying faults. | Significantly improves system reliability and reduces the likelihood of immediate breakdowns. |

| Efficiency | May not improve efficiency if the pump is old and inefficient. | Modern pumps are often more energy-efficient, leading to lower operating costs. |

| Peace of Mind | May offer short-term relief, but concerns about future failure might persist. | Greater peace of mind knowing a critical component is new and under warranty. |

If your pump is old or has failed multiple times, boiler pump replacement is usually the most sensible financial choice. When repair costs approach the price of a new pump, replacement is a clear winner.

Factors Influencing Boiler Pump Replacement Costs

Several factors affect the final price for a boiler pump replacement:

- Pump type and brand: Costs range from basic models to high-efficiency “smart” pumps that can lower energy bills over time.

- System accessibility: A pump in a tight or hard-to-reach space increases labor time and cost.

- Need to drain the full system: Systems without isolation valves require a full system drain and refill, which is more time-consuming.

- Regional labor rates and emergency fees: Emergency and after-hours calls naturally cost more. Addressing warning signs early can prevent these extra charges.

- Additional repairs: Sometimes, replacing a pump reveals other issues, like system pressure problems that also need to be addressed. Learn more in our guide on boiler pressure problems and solutions.

Can a Boiler Pump Be Repaired?

The short answer is sometimes, depending on the pump’s age and the specific problem.

- Seized components: A technician can sometimes free a seized impeller, but it’s often a sign of underlying sludge issues or age, meaning it will likely happen again.

- Minor leaks: Leaks from fittings can be tightened, but if the pump housing itself is corroded and leaking, it must be replaced.

- Electrical connections: A loose wire is a simple fix, but a failed internal motor requires a full replacement.

When is replacement more economical? Our rule of thumb: if the pump is old, has a history of issues, or repair costs are more than half the price of a new one, replacement is the better investment. Modern pumps are also more energy-efficient, offering long-term savings on utility bills.

Our team provides an honest assessment of whether repair or replacement is best. For more guidance, see our article on when to call for boiler repair.

Choosing the Right Pump & Future-Proofing Your System

Once you’ve decided on a boiler pump replacement, choosing the right model is an opportunity to improve your system’s efficiency and reliability. A new pump should last 10-20 years with proper maintenance, making it a key investment.

When selecting a replacement, our experts consider:

- System Compatibility: The new pump must match your boiler’s flow rate, head pressure, and pipe connections.

- Proper Sizing: An undersized pump causes cold spots, while an oversized one wastes energy and causes noise. Correct sizing is crucial for performance.

- Energy Efficiency: Modern pumps with ECM (electronically commutated motor) technology use significantly less energy, leading to savings on utility bills.

- Brand and Reliability: We recommend reputable brands known for quality and durability, ensuring your investment lasts.

Proper installation is key to maximizing lifespan. You can find more insights in our article about the importance of proper pump installation.

Types of Boiler Pumps

While all circulators move water, there are a few common types:

- Circulator Pumps: This is the general term for pumps in a closed-loop heating system. Most residential boiler pumps are circulator pumps, designed for quiet, reliable operation.

- Wet Rotor Pumps: A common design where the motor’s rotor is cooled and lubricated by the system’s water, ensuring quiet operation. Many popular models use this design.

- High-Efficiency Models: These pumps use modern ECM motors and can adjust their speed based on demand, consuming far less electricity than older single-speed pumps.

- Smart Pumps: The most advanced pumps feature intelligent controls that self-adjust to optimize performance and can integrate with smart home systems.

Maintenance to Extend Pump Life

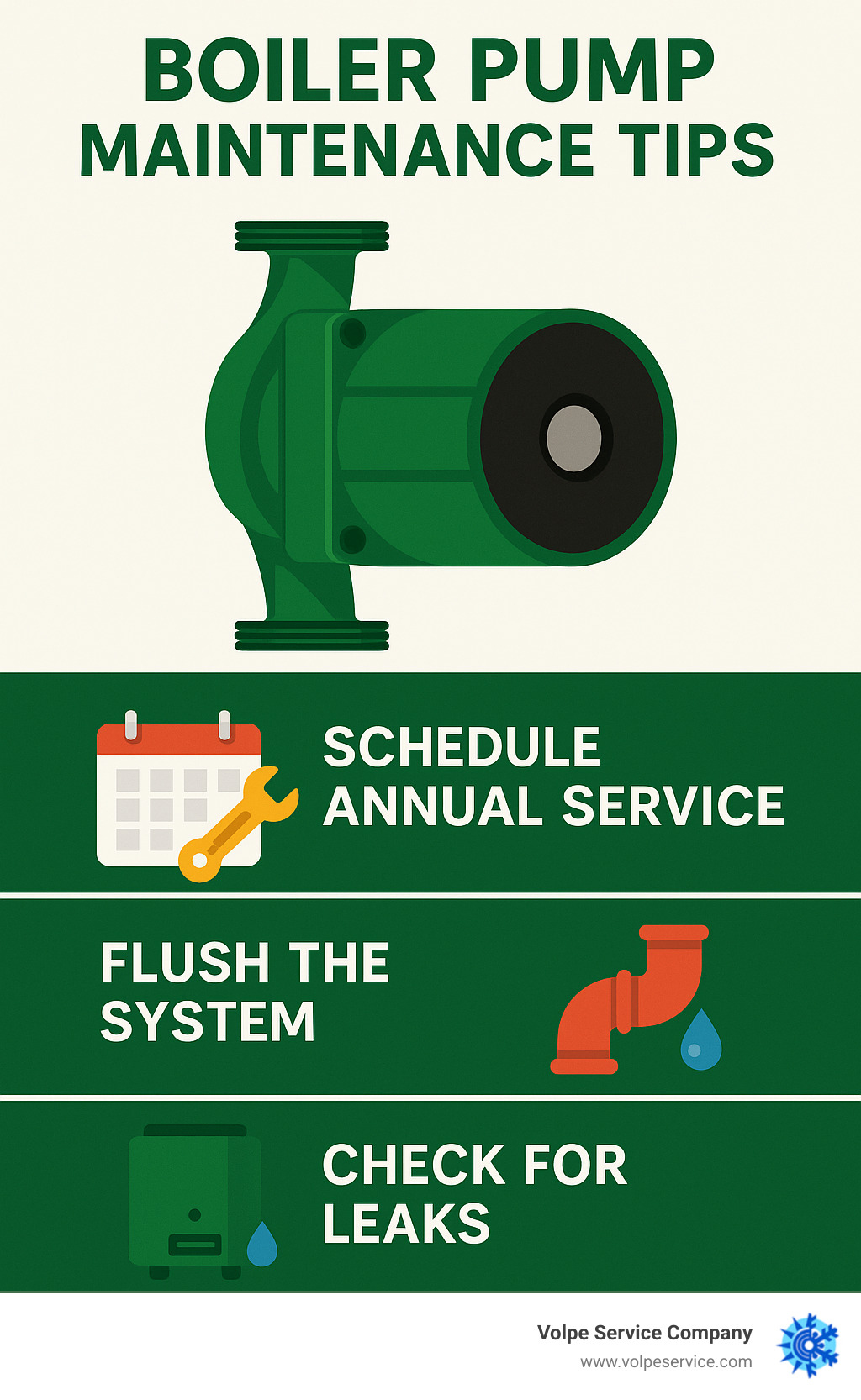

Consistent maintenance can significantly extend your pump’s life and help you avoid a premature boiler pump replacement.

Here’s what we recommend:

- Annual Boiler Service: This is paramount. A yearly professional service is the best way to ensure pump longevity and keep your warranty valid. During a service, a technician inspects the pump for wear and ensures it’s operating correctly. Here are 5 reasons for annual boiler service.

- Flushing the System: A system flush removes sludge and debris that can clog or seize your pump.

- Checking for Leaks: Regularly inspect the pump and surrounding pipes for any drips or signs of corrosion.

- Bleeding Radiators: Trapped air strains the pump. Bleeding radiators ensures efficient circulation and reduces the pump’s workload.

- Maintaining System Pressure: Keep your system’s pressure within the manufacturer’s recommended range to avoid putting stress on the pump and other components.

Proactive maintenance is always less stressful and more affordable than emergency repairs. For more tips, check out our guide to get essential boiler service tips.

Conclusion: Restore Your Home’s Comfort and Efficiency

Understanding your boiler pump replacement options puts you in control of your home’s comfort. A functional pump is the heart of your heating system, essential for distributing the heat your boiler produces. Without it, you’re left with cold radiators and no hot water.

The good news is that modern pumps offer significant benefits. Today’s high-efficiency models are quieter, more reliable, and use far less energy, which can lead to noticeable savings on your utility bills.

At Volpe Service Company, we’ve helped New Jersey families stay warm since 1963. Our data-driven solutions mean we diagnose the real problem and fix it right the first time. We provide honest advice—if a repair is cost-effective, we’ll tell you. If replacement makes more sense, we’ll explain why.

Heating problems are never convenient, which is why our guaranteed service provides peace of mind. When we complete your boiler pump replacement, you can count on reliable heat for the winter ahead.

Don’t let a failing pump compromise your comfort. Whether you’re hearing strange noises or dealing with a complete breakdown, we’re here to restore your home’s warmth and efficiency.

For expert heating repair in East Hanover, NJ, contact us today!